Macoga specialises in expansion joints used in FCCU applications and partners with Dawcul to facilitate the fulfillment of Refractory lined Expansion Joints for FCCU (Fluidized Catalytic Cracking Units) in markets such as Bulgaria, the Czech Republic and Romania.

Types of FCCU Expansion Joints

Typical types of expansion joints used in FCCU applications are: Restrained Universal, Gimbal, Hinged and Pressure Balanced (in-line and elbow type) and can be categorized in three major groups:

- Cold Wall

- Hot Wall

- Unlined

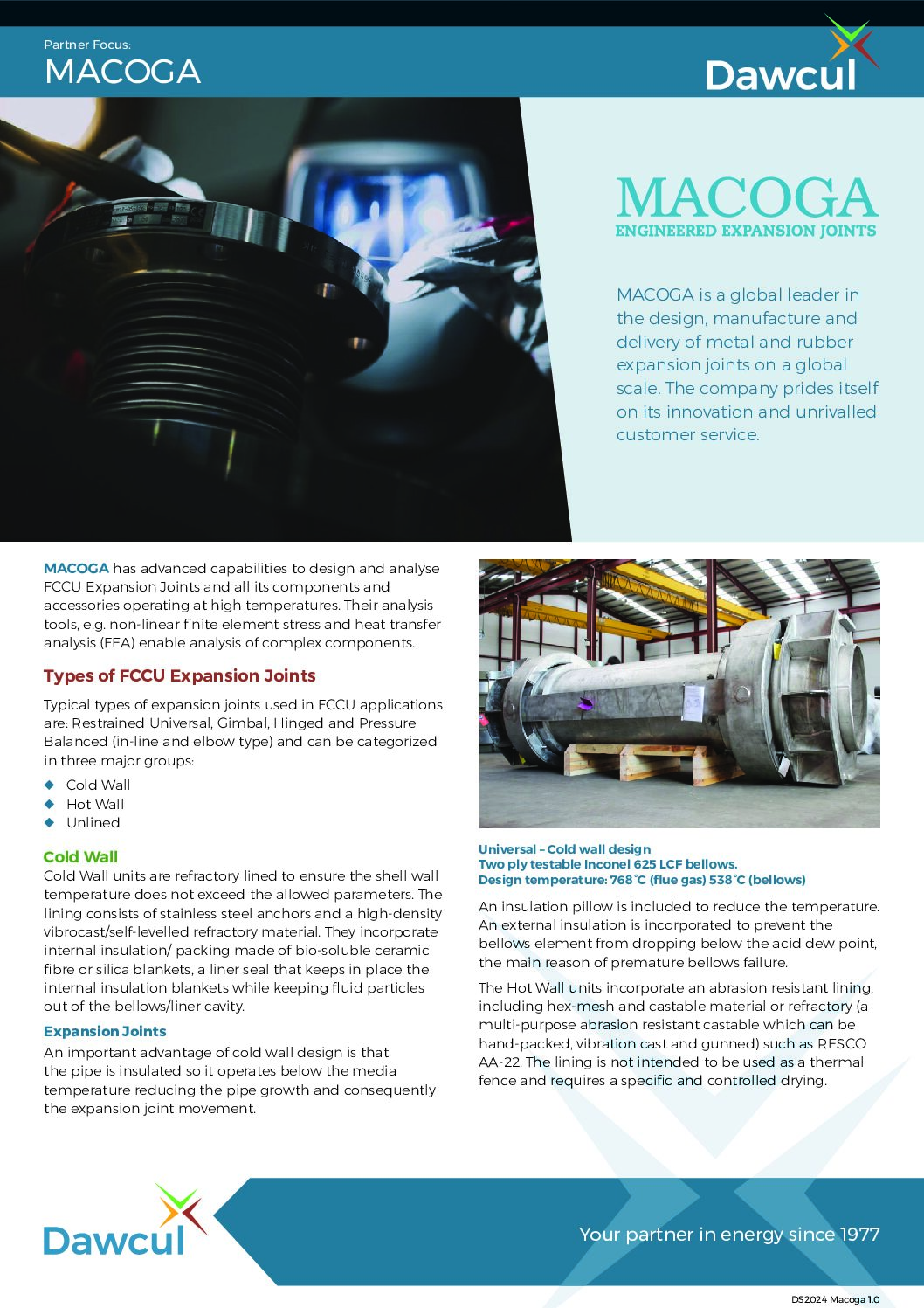

The Cold Wall units are refractory lined to ensure the shell wall temperature does not exceed the allowed parameters. The lining consists of stainless steel anchors and a high-density vibrocast/self-levelled refractory material. They incorporate internal insulation/ packing made of bio-soluble ceramic fibre or silica blankets, a liner seal that keeps in place the internal insulation blankets while keeping fluid particles out of the bellows/liner cavity.

An important advantage of cold wall design Expansion Joints is that the pipe is insulated so it operates below the media temperature reducing the pipe growth and consequently the expansion joint movement.

An insulation pillow is included to reduce the temperature. An external insulation is incorporated to prevent the bellows element from dropping below the acid dew point, the main reason of premature bellows failure.

The Hot Wall units incorporate an abrasion resistant lining, including hex-mesh and castable material or refractory (a multi-purpose abrasion resistant castable which can be hand-packed, vibration cast and gunned) such as RESCO AA-22. The lining is not intended to be used as a thermal fence and requires a specific and controlled drying.

The Unlined FCCU Expansion Joints can be exposed to very high temperatures but usually do not convey catalyst so they do not require abrasion resistant lining. This type is generally used for inlet and outlet air and transferring gases from the reactor.

Refactory Materials and Installation

Refractory is a major element of all FCC components. Without proper refractory installation the process unit is risking a costly unscheduled unit shutdown. FCC Expansion Joints are designed with a hot wall (external insulation) or cold wall (internal insulating refractory). The internals that are exposed to catalyst erosion are protected with abrasion resistant refractory even in hot wall designs.

Generally, all these critical linings are designed and installed according to the most up-to-date and demanding refractory licensors specifications as UOP 3-series, ExxonMobil Research and Engineering EMRE Gp, KBR and API 936 or proprietary own specifications.

The insulating or abrasion resistant refractory linings can be installed by casting, gunning (pneumatic application), hand-placing or pneumatic ramming. The abrasion resistant refractory installation involves several critical activities like anchor system (hexmesh or equivalent), QC of materials, prequalification, application and heat dry outs. It is very important that all refractory installation activities are, during all the process, carefully controlled to ensure a good quality control through a good method statement with drawings, materials selection, testing frequency, installation systems and dry out curve.

FCCU Expansion Joint On-Site Services

We help you get them properly installed. In any refining facility the FCCU Expansion Joints are critical units that require a high level of expertise during installation and maintenance to ensure that the refining process is not disrupted and optimal production can be achieved.

MACOGA offers its customers in the oil and gas, refinery and petrochemical industries a complete field service package.

We provide a professional variety of site services including assembly, supervision of installation and inspection that minimize risks of unplanned shutdowns and help to avoid failures and breakdowns.

Assembly of the Expansion Joints

Our site team is trained and consists of qualified welders, technicians and engineers who work in plants and refineries worldwide. Thanks to our many years of experience in manufacturing and installing FCCU Expansion Joints we know what matters.

A site-specific erection plan is developed during one or more pre-construction conferences and site inspections involving the customer, the contractor, and others such as the project engineer.

MACOGA manages all aspects of site work for the Expansion Joints supplied. From initial delivery of the equipment to site, installation to agreed standards, and final commissioning, MACOGA will manage the project.

Assembly Supervision

Qualified and trained engineers are available for guidance and instruction during assembly and/or erection process (by others) of our Expansion Joints. We offer pre-instruction and guidance for assembly and periodical inspections that guarantee the correct procedures are being carried out and unquestionably a Final Inspection after completion of the assembly and/ or erection works.

Additional services available include Nondestructive Examination.

For details of the FCCU Expansion Joints on-site inspection services, please download the Macoga datasheet.

Dawcul is a Trusted Distributor for Macoga

Dawcul recently worked with Macoga installing regenerator cyclones in a refinery in Romania. You can read more about this project here.

For expert advice on procurement, logistics and installation talk to one of our local experts across Eastern Europe.

MACOGA customer on site inspection

Dawcul Area Manager for Lithuania, Arijus Skarbalius, and Company CEO, James Bovill, were very pleased to welcome Simon Stanway from Macoga SA to Orlen Lietuva Refinery in the Mazeikia region of Lithuania in February 2024.

Dawcul Area Manager for Lithuania, Arijus Skarbalius, and Company CEO, James Bovill, were very pleased to welcome Simon Stanway from Macoga SA to Orlen Lietuva Refinery in the Mazeikia region of Lithuania in February 2024.

The morning presented an opportunity to inspect Macoga’s expansion bellows on the Refinery’s FCCU (Cat Cracker) and present our partners’ significant experience and regional coverage to both the maintenance and procurement departments.

This allowed for discussion and understanding at a deeper level, making the most of the face to face meeting and seeing Macoga’s products on site.

Can we help you in any way?

To arrange an initial chat with one of our expert advisors, please complete the form and we will be in touch.