Sulzer Chemtech is a global leader in fluid engineering and chemical processing applications. The Chemtech Division is the global market leader in innovative mass transfer, static mixing and polymer solutions for chemicals, petrochemicals, refining and LNG.

Refining, petrochemical and chemical companies around the world apply Sulzer’s advanced technology to optimize production capacity and efficiency, reduce operating costs and minimize environmental impact.

Products and services

Process Plants

Sulzer has an innovative range of separation technologies to fully develop process plants from initial concept and pilot testing to start-up. Their services support plant processes, benefiting from extensive experience in the chemical industry.

Pilot plant, process verification and performance guarantees

The Sulzer Chemtech experts develop individual process solutions, supported by simulations and / or studies. The final verification with customer feed is then conducted in their test center in Allschwil, Switzerland. Sulzer Chemtech has actually performed over 1,000 pilot tests, thus creating confidence and the offering of a guaranteed plant performance, going forward.

Basic engineering

Sulzer provides basic engineering packages as an initial step in the delivery of a skid-mounted unit, or together with the supply of proprietary key equipment e.g. for a new separation unit.

Detail engineering

Sulzer’s team of engineers and technicians will define in detail all the required information when designing your process plant solution and will provide clear and professional documents.

Proprietary equipment

All key equipment is produced either in Sulzer’s state-of- the-art workshop or sourced from approved and certified sub suppliers. Continuous development of equipment ensures that you receive maximum value from your investment.

Project management

Competent and experienced project managers ensure the successful implementation of your project and keep you informed on the progress. Every stage of each Sulzer project is governed by a quality assurance system that is accredited in accordance with ISO 9001.

Skid mounted plants

Accelerate your project with Sulzer’s skid-mounted plants. Benefit from high-quality work with less site disruption. This type of plant assembly offers many advantages over conventional on-site construction.

Installation, commissioning and start-up

Highly experienced installation supervisors and start-up engineers will support you in the erection, installation, commissioning, and start-up of your new plant.

Life cycle management

Improvements can be implemented at any time to increase service life, improve availability, reduce emissions, or simply deliver the right parts and labour quickly. Sulzer has significantly expanded and improved its global after-sales network.

Unit operations and technologies

Distillation and Absorption

With an extensive offer of distillation components and internals, Sulzer provides the most efficient separation process, enabling each plant to remain competitive and access new levels of product quality.

Absorption technology

Process specialists help to optimally design wash columns, and supply first-class components, equipment, and plants with an excellent performance/cost ratio.

Distillation technology

Distillation is the most commonly applied separation technology. Sulzer has been supplying process solutions in this field since 1940. To date, more than 100,000 columns are operating with Sulzer equipment, in over 500 different applications.

Stripping technology

Process specialists support you with optimally designed stripping columns. Sulzer provides first-class components and equipment, or entire plant solutions, delivering an excellent performance/cost ratio.

Evaporation

Evaporation systems are available for product evaporation, concentration or solvent recovery. Sulzer can also treat heat-sensitive, viscous and complex products, and provide reboilers for distillation systems.

For more information about evaporation products, please download the Sulzer datasheet.

Liquid-liquid Extraction

Liquid-liquid extraction is a technically advanced separation technology. It is applied when simpler alternatives such as distillation are not able to meet requirements. Components are extracted from the feed with the help of a solvent, without an energy demanding evaporation step.

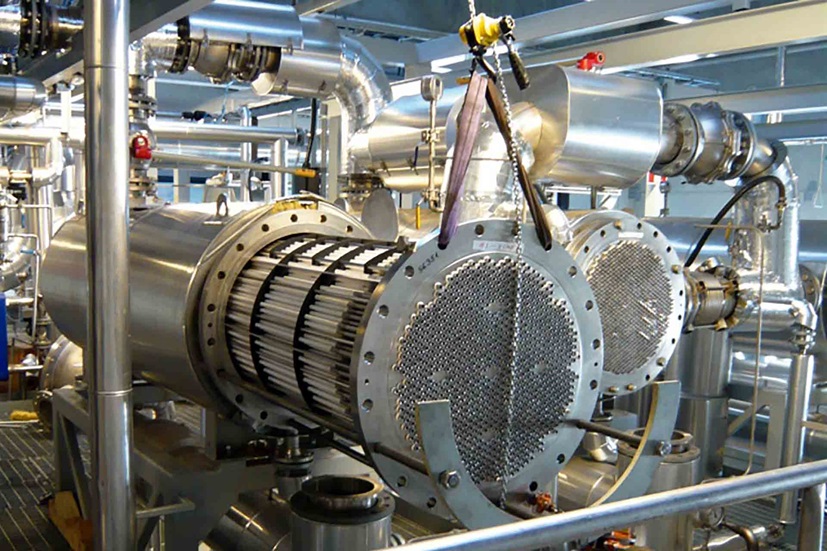

Kühni agitated liquid-liquid extraction column

In extraction with high mass transfer and/or changing physical properties, this is the column of choice. The geometry of the agitated compartments can be adapted for changing hydrodynamic conditions. Other main features are special mixing turbines and perforated partition plates.

For more information about extraction columns products, please download the Sulzer datasheet.

Process and Application Development

Sulzer continuously challenges the boundaries of established technology to develop processes and applications that yield higher-value products, have a smaller footprint, are safer to operate, more environmentally friendly, more energy efficient and more economical. It gives customers a competitive edge and improves their environmental credentials.

Solvent recovery systems

A cost-effective and efficient solvent recovery system can deliver both economic and environmental benefits. Sulzer dedicates much of its effort to customizing solvent recovery systems.

Product purification

With the technical challenges facing high-purity products, Sulzer’s expertise in a wide range of different unit operations ensures their process solutions will satisfy your stringent requirements.

Biofuels and biochemicals

Sulzer offers sustainable and profitable options for biofuels and biochemicals. Their process solutions are geared to separate and purify biofuels and biochemicals.

Industrial Wastewater Treatment Technologies

Wastewater very often contains chemicals, which need to be removed before the effluent water can enter a biological treatment plant. Sulzer Chemtech’s technologies can remove these chemicals by applying its technologies. Removal of heavy boilers such as phenol by utilising liquid-liquid extraction or removal of light boilers such as ammonia by applying stripping processes.

For more product and specification information, please download the Sulzer Chemtech datasheet.

Dawcul is a Trusted Distributor for Sulzer Chemtech Process Plants

For expert advice on procurement, logistics and installation talk to one of our local experts across Eastern Europe.

Photos courtesy of Sulzer

Can we help you in any way?

To arrange an initial chat with one of our expert advisors, please complete the form and we will be in touch.