Plenty has over 60 years of operational experience utilising swivel angle mixing technology. The company provides fixed angle mixers for blending, homogenizing and temperature uniformity duties, and swivel angle mixers for tank cleaning operations and prevention of sludge settling. All mixers permit the bearings and mechanical seal to be changed under full tank conditions. The Plenty Side Entry Impeller is designed with minimum diameter, no cavitation, high concentrated thrust, high fluid flow and minimum power draw.

SPX Flow Heavy Duty Side Entry Mixers

The Plenty Side Entry Mixer is an efficient converter of energy into fluid motion. Unlike jet mixer systems it does not suffer significant energy losses at the pump, in the pipework, in the bends, or most significantly, at the jet nozzles. Capital costs are low and access to in-tank components is not restricted, and the problem of frequent, urgent maintenance on tanks that must be emptied and cleaned is eliminated. Side Entry mixers are also efficient and are usually less expensive for larger diameter tanks and are ideal for use on tanks with floating roofs where practical considerations preclude the use of top entry mixers.

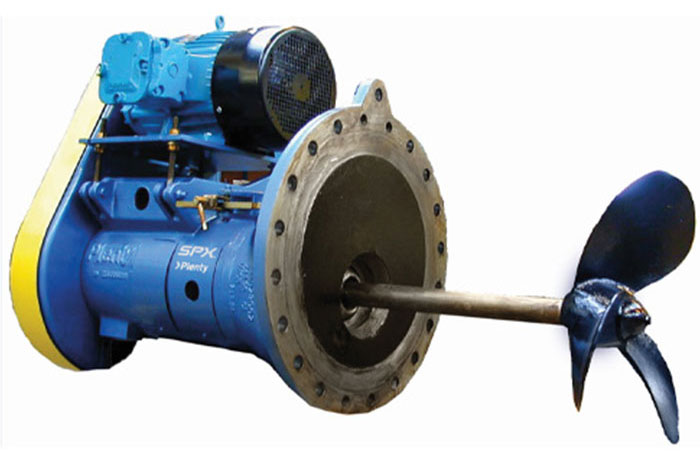

Impellers

Developed by Plenty for Side Entry Mixers, the high efficiency true helical pitch impeller with forward rake is a technically advanced design, having a large blade area that provides the optimum cavitation-free suction conditions promoting maximum pumping rate and entrainment for any installed power. Each impeller is accurately cast as a one-piece component, thus eliminating the setting variances and welding problems often present with alternative fabricated designs. Rigid inspections of pitch, uniformity and balancing ensure minimal vibration and optimum pumping efficiency.

Tank Mounting Manhole – Fixed And Swivel

The most common sizes of tank adaptor flanges to suit ANSI and API standard 24” and 30” are available as standard. Tank adapter flanges can be supplied to suit all tank manhole/nozzle fixings.

Gear Driven Mixer

Driven by a vertical electric motor which is flange mounted on the support bracket above the gearbox and connected by an all metal flexible coupling protected by a guard.

Belt Driven Mixer

A horizontal foot mounted motor is fitted above the main mixer frame on a steel mounting plate which allows adjustment for correct belt tensioning. Motor mounting plate hinges and belt adjustment screws are corrosion protected against atmospheric corrosion.

Shafts

Designed to minimize misalignment, deflection and vibration which all affect the mechanical seal and bearing life. A one-piece component with no intermediate couplings and is ground between centers at the bearing and seal areas. All shafts are hardchrome plated in seal and shut off areas.

Unique Tank Shut-Off Device

All units incorporate a tank shut-off device to allow the shaft seal and bearings to be changed under full tank conditions. The tank shut-off mechanism incorporates tapered metal to metal faces, positively clamped by a bolted flange which both seals products in the tank and securely supports the shaft during bearing and/or shaft seal changes. The Plenty shut-off mechanism offers complete safety and security as it does not incorporate flexible ‘O’ rings or gaskets which deform, wear or perish.

Crude Oil, Bottom Sludge and Water (BS&W)

The main purpose of the mixers in this application is to ensure the developed jet flow is used to lift the BS&W into the body of the crude oil to maintain a relatively clean tank floor.

For more product specification information please download the SPX Plenty product specification datasheet.

Dawcul is a Trusted Distributor for SPX

For expert advice on procurement, logistics and installation talk to one of our local experts across Eastern Europe.

Can we help you in any way?

To arrange an initial chat with one of our expert advisors, please complete the form and we will be in touch.