Tank Aluminum Cover (TAC) is a company that specializes in manufacturing, supply, engineering and installation of environmental equipment for the reduction of VOC from the storage equipment in the petrochemical companies. TAC is considered as an experienced manufacturer of Aluminum Geodesic Domes, Seals, Covers, Internal Floating Roofs, Drain Systems and Suctions.

TAC experience and capacity has qualified the company to obtain the support of the main worldwide clients (like BP, Eni, Repsol, CLH, YPF, Petrobras, Cepsa, Saras…) in various countries across the globe. Experience, talent, quality and the capacity to adapt to market changes and fluctuations have made TAC a company of international repute in the highly regarded field of industrial projects.

Main products

Aluminium Dome Roof

- The assembled structure complies with the design requirements API 650 Appendix G.

- Lowest cost solution and short-term payback.

- Eliminates rainwater entry and possible product contamination.

- Prevents the possibility of a sunk roof due to rain or snow accumulation.

- Easy to install (plus minimum downtime).

- Maintenance-free structure due to all aluminium construction.

- Strong, durable and corrosion resistant.

- Lightweight design (minimal additional weight to existing foundations).

- Makes all the problems associated with either hose or pipe drains obsolete.

- Protects the existing seals from ultraviolet and other environmental hazards.

- Minimum evaporation losses.

Internal Floating Roof – Pontoon

- The assembled structure complies with the design requirements API 650 Appendix H.

- Calculation and design done according to EUROCODE.

- Matrix Methods of Structural Analysis.

- The construction material can be Aluminium or Stainless Steel in accordance with API 650 Appendix H.

- The materials are compatible with a broad range of stored products.

- Strong enough to support all sealing systems, including both primary and secondary metal seals.

- Extruded aluminium floats with no longitudinal welds to improve safety and increase working life. Pontoons under pressure factory tested.

- All components fit through manway for quick, easy installation.

- Its combination with an Aluminium Geodesic Dome provides a maximum control of losses or emissions and the maximum utilization of the storage capacity.

Internal Floating Roof: Full Contact

- The construction material can be aluminium or Stainless Steel, according to API 650 Appendix H.

- Its combination with an aluminium Geodetic Dome, provides maximum control in the loss of emissions as well as a maximum use of storage capacity.

- The materials are compatible with a wide range of stored products.

- Employs a single panel design. Each module is fully tested in the factory to verify the tightness of the vapors and can be individually inspected in the field.

- Does not use complex or dangerous material inside.

- It does not use supports that perforate the platform, either using cables or legs to support the roof. This reduces leakage losses from drilling at very low levels compared to traditional carbon steel screens.

- It is strong enough to withstand all sealing systems, including both primary and secondary metal seals.

- Light weight structure with exceptional strength, using patented construction techniques.

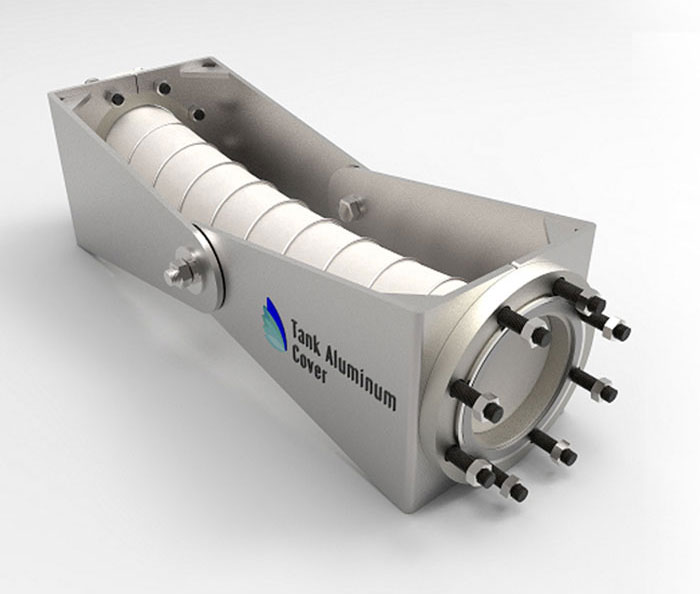

Floating Suction

- The Floating Suction System is designed to eliminate the accumulated product on the surface of the stored product.

- It is designed to work in tanks of any size, with all types of floating roof and with components compatible with any stored product.

- The design is made for each specific case, guaranteeing a long life free of worries.

Drain System

- Drain Joints are an innovative design incorporated to meet specific requirements for floating roof drainage systems. The elasticity of Flexible systems is combined together with the strength of Swivel Joints.

- Side plates are available in galvanized steel (standard) or as an option in stainless steel and redistribute the load around the flexible hose, minimizing the possibility of hose failure.

- Fixed position (limited scraping).

- Compatibility with an extensive product range.

- High operating pressure.

- Free water flow due to continuous slope.

- Stress and load-free hose end connections.

- No lubrication required.

For more products and product specification information please download the TAC datasheet.

Dawcul partner with Tank Aluminium Cover

Dawcul recently project managed the installation of Tank Aluminium Covers onto oil storage domes in Croatia. Find out more here.

For expert advice on procurement, logistics and installation talk to one of our local experts across Eastern Europe.

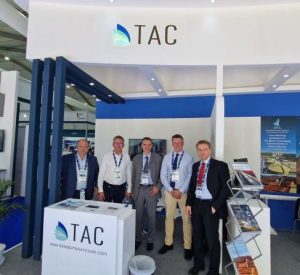

ADIPEC 2023

ADIPEC 2023 (Abu Dhabi) provided Dawcul with an opportunity to catch up with many great partners, including TAC (Tank Aluminium Cover). Dawcul’s Managing Director, James Bovill, alongside Tomasz Milewski and Asen Petrov, had the opportunity to meet Jose Pozo, Managing Director of TAC, and Serhiy Komarchyn, Regional Director of TAC. They were exhibiting as part of the Spanish Pavillion at ADIPEC 2023.

ADIPEC 2023 (Abu Dhabi) provided Dawcul with an opportunity to catch up with many great partners, including TAC (Tank Aluminium Cover). Dawcul’s Managing Director, James Bovill, alongside Tomasz Milewski and Asen Petrov, had the opportunity to meet Jose Pozo, Managing Director of TAC, and Serhiy Komarchyn, Regional Director of TAC. They were exhibiting as part of the Spanish Pavillion at ADIPEC 2023.

We look forward to returning to Seville to meet with our colleagues in the next few weeks.

Can we help you in any way?

To arrange an initial chat with one of our expert advisors, please complete the form and we will be in touch.