Dawcul’s partnership with Autocontrol Technologies focuses on product sampling in the oil and petrochemical industries when custody transfer takes place. It has a range of products designed to conduct automatic refined product sampling with high measurement accuracy to ensure quality of product is maintained.

Product sampling is recommended to guard against contamination or higher than acceptable water content which has the potential to greatly reduce the value of the product. It cuts costs over time, providing a return on investment and quality assurance guarantees.

Inline samples are taken where needed, for example on ships, along pipelines, on offshore oil platforms, tankers and metering skids, and laboratory tested on a regular basis to monitor performance.

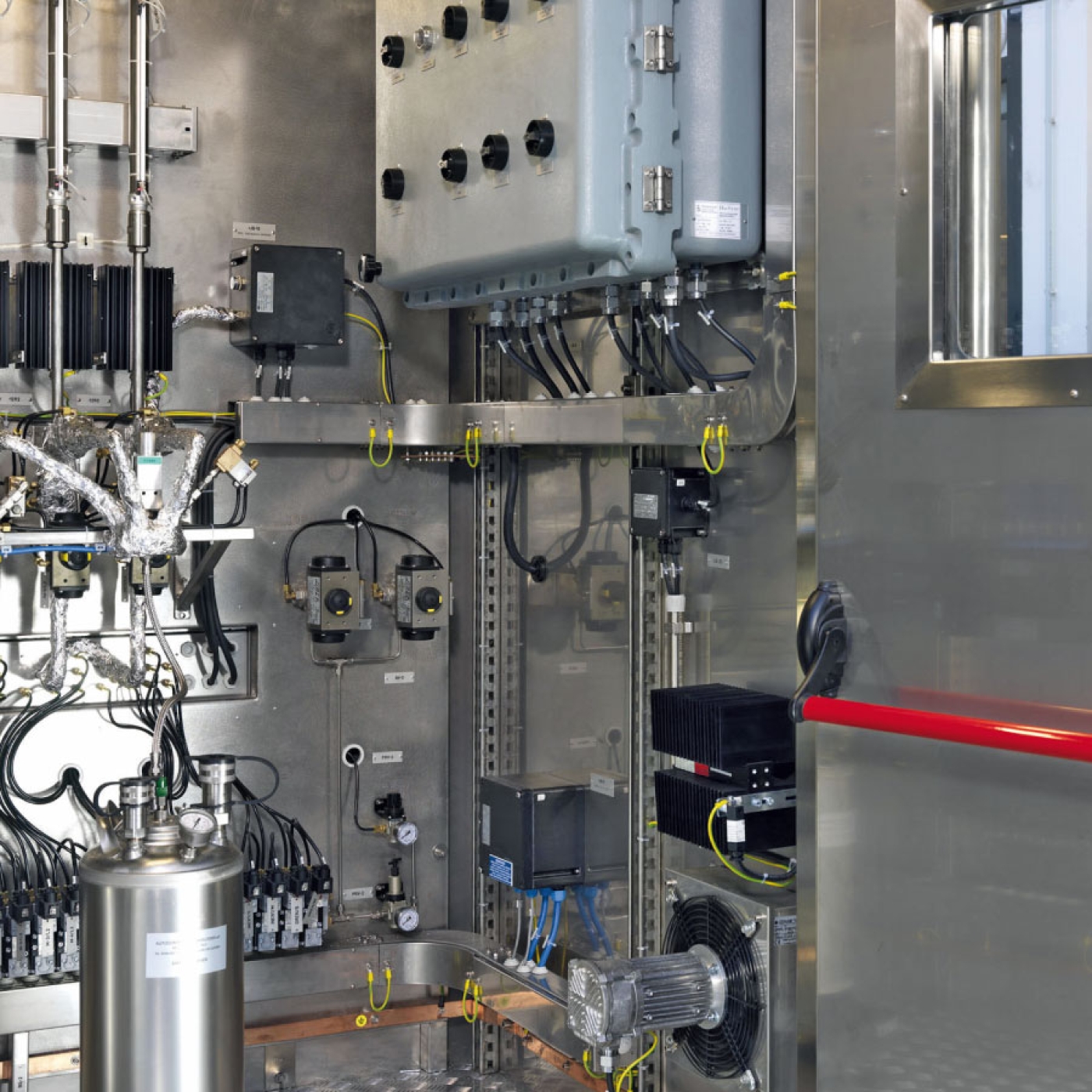

Established in 1994 to offer customers cutting edge solutions in the on-line instrumentation, process measurement and control automation fields the company’s core business is in Design, Engineering, Construction and Installation of high technology process instruments for the Oil & Gas, Petrochemical, Chemical and Power industries.

Products

DyMix®

DyMix®

Dynamic mixer system

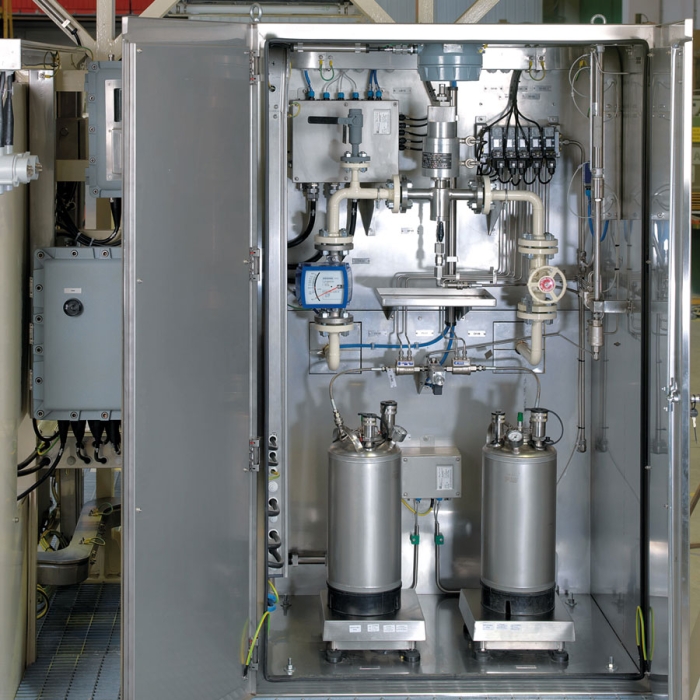

Available for lines with diameters of up to 60″, the system is accurately sized to generate enough power to correctly mix the pipeline content.

It can be used together with an in-line sampling system or combined with a fast loop circuit and cell sampler.

The system can be supplied with two redundant pumps for reducing the maintenance downtime to zero, allowing it to operate with one of the two pumps.

SmartLoop®

SmartLoop®

Fast loop system

The smart loop sampling system implements the classic bypass solution and is ideal when many different inline measuring devices need to be inserted. The system is designed according to the specific needs of each single application.

Prime

Prime

Single and multiple line premium technology

Custody transfer applications often occur on piers where the best sampling point is found on the loading/unloading arms. In these situations, there is usually a chronic lack of space which leads to difficulties in adding a mixing device.

The unloading arm is the best sampling point available due to the presence of the ship’s pumps, valves, reductions and bends upstream of the sampling point, which guarantee almost perfect mixing. In this case, a multiple in-line sampler is highly suitable, reliable and perfect for the job.

First-90

First-90

Low cost single line

First-90 is Autocontrol Technologies smallest sampling system but also one of the toughest, it can manage one sampling point and is suitable for the harshest environments due to its stainless steel construction (it has been used in off-shore platforms, terminals and refineries).

It can be managed locally or remotely by its dedicated SWIFT Sample Controller. A DCS/SCADA interface is also available via Dry-Contacts or Modbus lnterface for easy integration with customers’ systems

EPASS

EPASS

Portable multiline

This portable system can be used when a fixed system is not a viable solution (e.g. where there is lack of space or infrequent sampling operations are needed).

EPASS runs on batteries and can deliver up to 48 hours of continuous sampling time, which can be easily extended by replacing the batteries without losing the sampling operation, it can be connected directly to the ship’s manifold with his specific spool pieces.

For more information and product details, please download the Autocontrol Technologies datasheet.

Dawcul is a Trusted Distributor for Autocontrol Technologies

For expert advice on procurement, logistics and installation talk to one of our local experts across Eastern Europe.

Can we help you in any way?

To arrange an initial chat with one of our expert advisors, please complete the form and we will be in touch.